Outline

| Section | Description |

|---|---|

| Introduction | Overview of banana cultivation and processing |

| Banana Cultivation | Steps involved in planting and growing bananas |

| Disease Management | Strategies to tackle common banana diseases |

| Banana Harvesting | Techniques and tools used for harvesting bananas |

| Banana Transportation | Methods to transport bananas post-harvest |

| Factory Processing | Steps in cleaning, packaging, and processing bananas |

| Banana Chips Production | Detailed process of turning bananas into chips |

| Conclusion | Recap of the banana processing journey |

Introduction

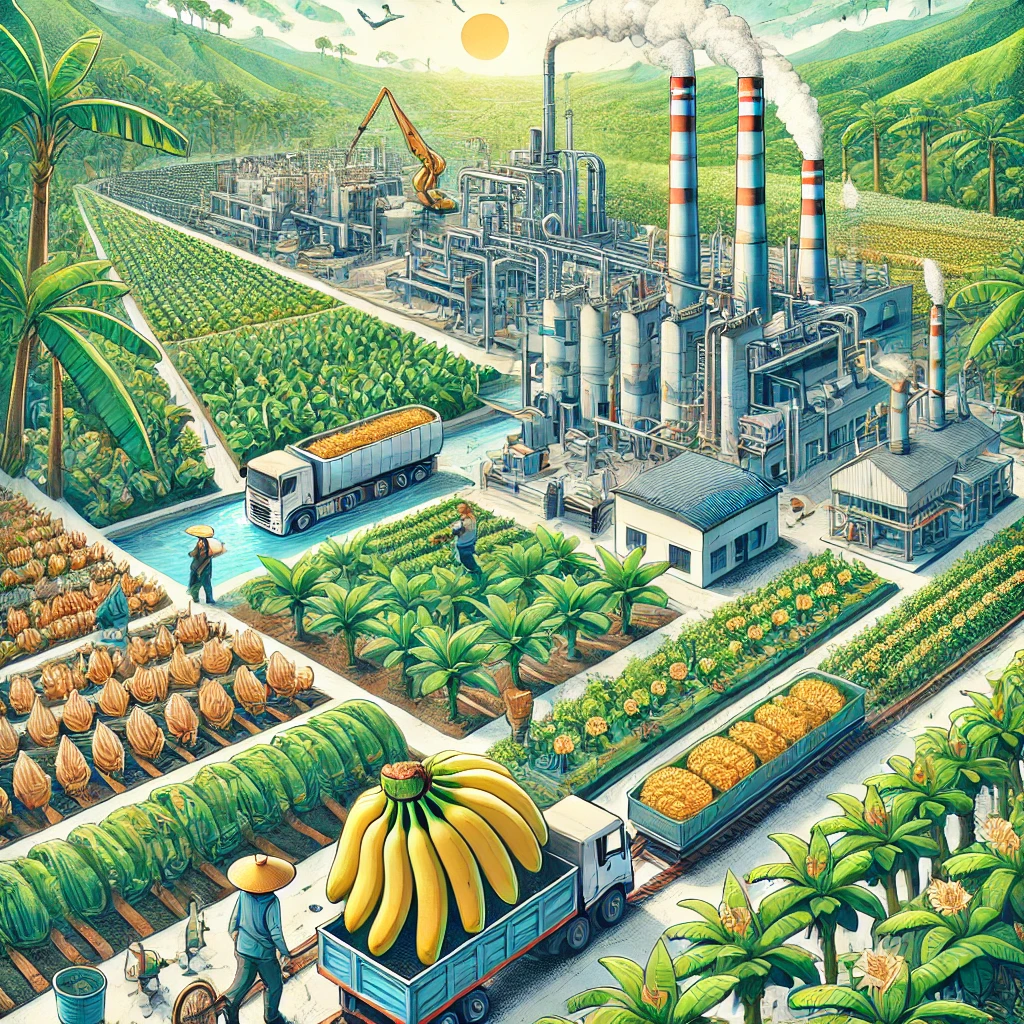

Bananas, one of the world’s most beloved fruits, have a fascinating journey from the field to your table. This blog explores the intricate processes involved in banana cultivation, disease management, harvesting, transportation, and factory processing, including the creation of delicious banana chips. Let’s dive in!

Banana Cultivation

The journey begins with careful field preparation and planting. Farmers arrange banana seedlings in rows using a cultivator, ensuring adequate spacing for optimal growth. Once planted, the seedlings are straightened, and fine mist sprays keep the soil moist, promoting healthy development. Depending on the banana variety, it takes 9 to 20 months for the seedlings to mature into full-grown plants.

Key steps in cultivation include:

- Pruning: Cutting the tip of the banana bud encourages cluster formation.

- Watering: Consistent moisture levels are maintained for optimal growth.

- Flowering and Fruiting: Farmers carefully trim parts of female flowers to expedite cluster development.

Disease Management

Banana plants are susceptible to various diseases, including Xanthomonas wilt and Sigatoka leaf spots. Effective disease control involves:

- Leaf Removal: Diseased leaves are promptly removed to prevent spread.

- Pesticide Application: Ground sprayers and aerial spraying techniques are employed to apply pesticides like Dimethoate and Methyl Dion 25 EC. These control common pests such as aphids and mites by targeting their nervous systems.

Banana Harvesting

Harvesting bananas requires precision and expertise. Farmers assess the size and ripeness of the bananas before cutting each bunch cleanly to prevent damage to the plant. In remote areas, manual harvesting methods are often preferred due to their efficiency and lower labor requirements.

Steps include:

- Cutting large, mature bananas while leaving younger ones to grow.

- Transporting bunches to the processing area using ropes or manual carriers.

Banana Transportation

Post-harvest, bananas are carefully transported to ensure quality:

- Workers tie banana bunches to ropes for easier movement.

- At the transport area, bananas are cleaned with water sprays to remove dirt and germs.

- Soft cotton padding is used between banana rows to prevent bruising during transit.

Factory Processing

In nearby banana factories, processing begins immediately to maintain freshness. Key steps include:

- Initial Cleaning: Removing cotton padding and thoroughly washing bananas.

- Bunch Separation: Dividing large bunches into smaller ones for detailed cleaning.

- Packaging: Workers weigh and pack bananas into polythene-lined trays, sealed to prevent contamination. Vacuum machines remove air from packaging to ensure freshness.

Banana Chips Production

Banana chips are a popular byproduct of banana processing. The production process includes:

- Peeling: Workers manually remove banana peels to expose the edible pulp.

- Grinding or Slicing: Pulp is either ground or cut into slices, depending on the desired chip style.

- Frying: Slices are fried in hot oil and passed through a rotating disc to extract excess oil.

- Flavoring and Packaging: Chips are seasoned, weighed, and packaged using AI-enabled machines for accuracy.

Conclusion

From planting seedlings to processing bananas into chips, each step of the banana’s journey reflects a blend of traditional farming methods and modern technology. This intricate process not only ensures quality but also highlights the dedication of farmers and factory workers in bringing this versatile fruit to your table.