Table of Content

- Introduction to Harvesting Innovation

- Modern Harvesting Machines Transform Agriculture

- Potato Harvesting: Precision and Power

- Cherry Harvesting: Delicate Yet Efficient

- Specialized Techniques for Different Crops

- Sugarcane Harvesting: A One-Time Investment

- Cabbage Harvesting: High-Tech Assistance

- Seasonal and Regional Harvesting Practices

- Lavender and Broccoli Harvesting Techniques

- Kiwi, Onion, and Grapes: Harvesting Across the Seasons

- Global Harvest Scenes and Practices

- Lotus Root and Citrus Harvesting in Asia

- Durian and Livestock Handling Practices

- Post-Harvest Handling and Value Addition

- The Mango Story: From Farm to Factory

- Value-Added Products: Juices, Snacks, and Beyond

- Frequently Asked Questions

- Conclusion

Introduction to Harvesting Innovation

Harvest season is a time of celebration and hard work, marking the fruition of months of labor. Today’s agricultural advancements, particularly in harvesting, bring together innovation, tradition, and efficiency to meet the growing demands of global food production. This blog explores fascinating harvesting techniques and machinery that are transforming agriculture worldwide.

Modern Harvesting Machines Transform Agriculture

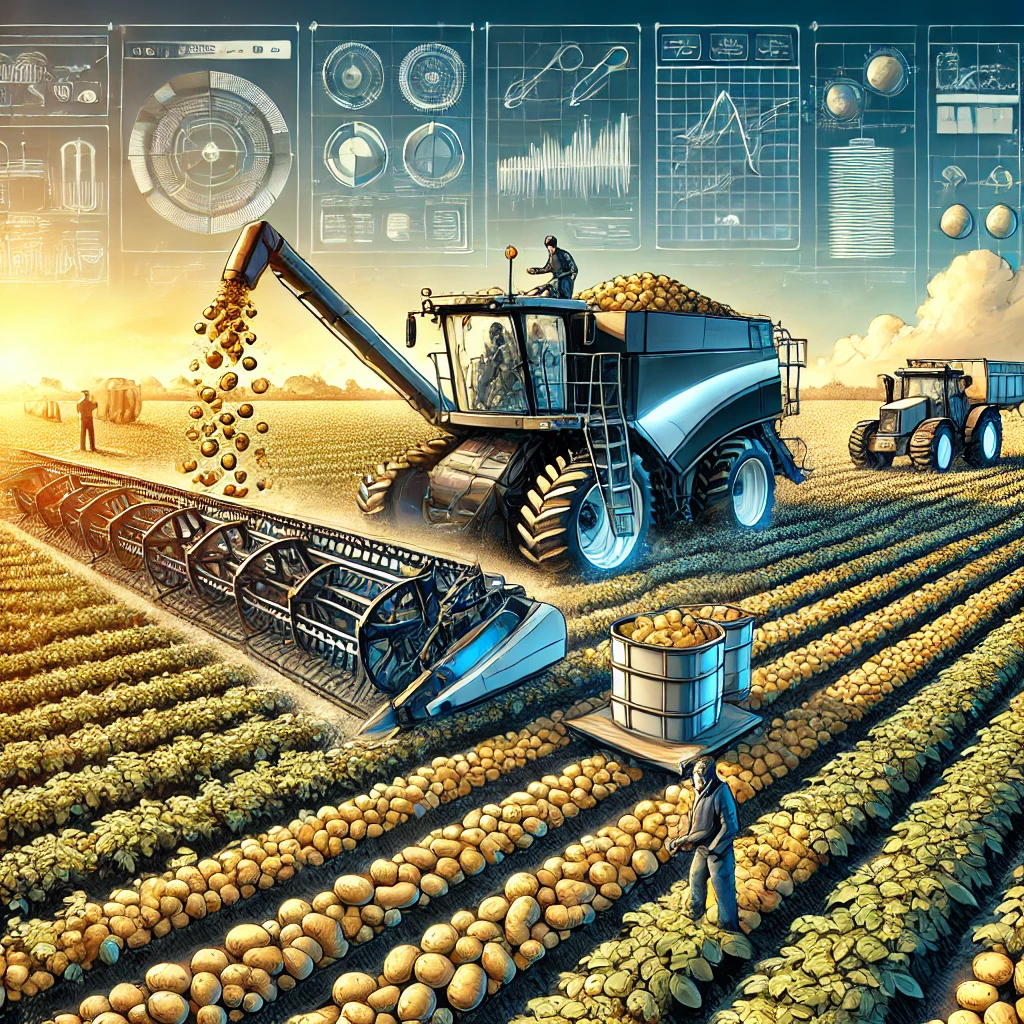

Potato Harvesting: Precision and Power

Potato harvesters are marvels of engineering. These machines can unearth and collect hundreds of potatoes in a single operation. Equipped with sorting systems, they minimize crop damage while cleaning and preparing the potatoes right in the field. In 2023, the U.S. harvested approximately 961 acres of potatoes, a feat made possible by these advanced machines.

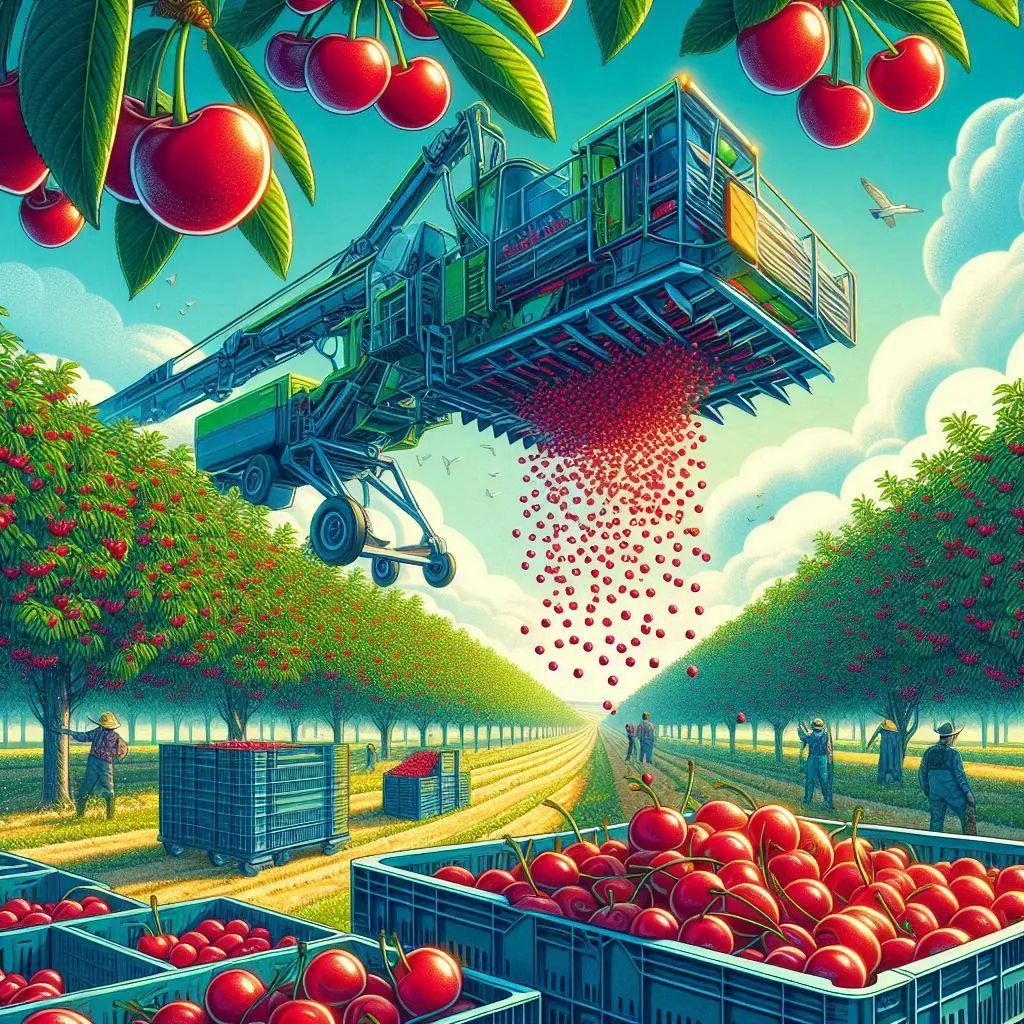

Cherry Harvesting: Delicate Yet Efficient

During cherry season, innovative harvesters gently shake trees, causing ripe cherries to fall without damaging their flesh. This method ensures high-quality produce and accelerates the supply chain. In 2023, U.S. cherry yields reached 550 million pounds, a testament to the effectiveness of these machines.

Specialized Techniques for Different Crops

Sugarcane Harvesting: A One-Time Investment

Sugarcane harvesters are transformative, performing the work of entire teams. These machines cut, clean, and load sugarcane in a streamlined process, with leaves repurposed as natural fertilizer.

Cabbage Harvesting: High-Tech Assistance

California leads in cabbage production, using advanced harvesters equipped with sensors to grip and cut cabbage heads cleanly. This efficient process ensures top-quality produce ready for markets.

Seasonal and Regional Harvesting Practices

Lavender and Broccoli Harvesting Techniques

Lavender is harvested delicately to maintain its aromatic properties, while broccoli fields come alive with swift manual and mechanical harvesting that preserves the vegetable’s quality.

Kiwi, Onion, and Grapes: Harvesting Across the Seasons

Kiwi and grape harvesting demand precision, often done manually to ensure ripeness. Onion harvesting involves carefully pulling and trimming roots, with workers often laboring through the night to avoid adverse weather conditions.

Global Harvest Scenes and Practices

Lotus Root and Citrus Harvesting in Asia

In Japan, lotus root harvesting is a meticulous process, requiring farmers to work submerged in muddy water. Similarly, traditional citrus harvesting in China emphasizes careful handling to maintain fruit integrity.

Durian and Livestock Handling Practices

Durian harvesting, though risky due to its spiky exterior, is done with precision to avoid fruit damage. Livestock handling, such as sheep and cattle, involves thorough health assessments to ensure stress-free transport and maximum market value.

Post-Harvest Handling and Value Addition

The Mango Story: From Farm to Factory

Mango farming highlights the importance of post-harvest care. From sap removal to sorting, packaging, and cold storage, every step ensures the fruit reaches markets in pristine condition. Globally, mango production exceeds 60 million tons annually, with India leading the pack.

Value-Added Products: Juices, Snacks, and Beyond

Mangoes are transformed into juices, dried snacks, and other delicacies. The production process involves washing, peeling, slicing, and drying, ensuring minimal waste and maximum flavor retention.

Frequently Asked Questions

Q: How do harvesting machines benefit farmers?

A: Harvesting machines save time, reduce labor costs, and improve efficiency, leading to higher yields and better product quality.

Q: What is the best season for harvesting mangoes?

A: Mangoes are best harvested early in the morning or late in the evening to prevent heat damage and ensure freshness.

Conclusion

From high-tech machines to traditional methods, the art of harvesting reflects the diversity and ingenuity of agriculture worldwide. Whether it’s precision-driven potato harvesters or hands-on mango picking, each method ensures that the fruits of labor are enjoyed at their finest.